Our commitment to customer services

that sets us apart from every one else.

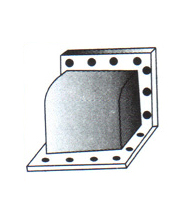

SB-3

Ductile and leak proof Joints

Typical Applications

Carbide tipping, joining sheet metal, joining at tubular steels, alloy and mild steel to stainless steel

Outstanding Features

Recommendations

High tensile low bonding temperature silver type alloy high strength joining on all metals except white metals. Excellent for joining brass, mild and alloy steel to stainless steel. For thin flowing applications on lap, 'T' square, butt and flange joints, ideal for thin and dissimilar gauge metals.

Procedure

Clean joint area. Highest strength joints obtained with clearance of 0.075 mm. Clamp parts when necessary. Heat broadly, using slightly excess acetylene. Keep distance 25 to 75 mm between the flame cone and base metal. Keeping torch in constant motion apply alloy till it flows completely through the joint. Remove flux residues.

Tensile Strength

40 Kg/mm2

Bonding Temperature

600°C