Our commitment to customer services

that sets us apart from every one else.

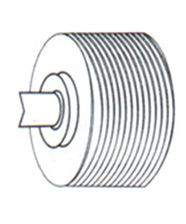

HF-4

Higher coefficient of friction, spray type high recovery welding alloy for super conditioning of sugar rolls and cane feed alloys.

Alloy base

Cr, Mo, V, W, Cb

Principle Features

Recommendations

HF-4 deposits on tooth point of cane crusher rollers. Especially suitable for arcing of cast iron and cast steel sugar mill crusher rollers, HF-4 is made up if complex carbides. Weld metal in globular form. These hard globule increase the effective surface area and this the pressure, resulting in lower level of moisture in bagasse. Excellent weldability in both dry and wet conditions without any change in diameter. It resists wear due to abrasion, adhesion, corrosion and impact.

Princial Applications

Specially designed for cast steel sugar mill crusher rollers.

Procedure

Use HF-4 to moving crushing roll at an speed of 5-7 R.P.M.. Weld on the side walls of the grooves and continuous contact with the roll keep & use directly on the sugar impact impregnated surfaces.

Hardness

550 BHN TO 650 BHN

Recommended Amperage AC/DC (+)

| Size (mm) | 4.0 | 5.0 |

| Current(AMPS) | 110-160 | 140-180 |